3D printing is undoubtedly one of the most disruptive technologies that have ever been devised in the history of human ingenuity and innovation. We are well aware of the immense potential of 3D printing technology to create prototypes for industrial manufacturing as well as functional objects. However, there has been a recent trend towards creating something much more long-lasting, i.e.memories in the form of 3D printed photo frame made with a lithophane.

Understanding Lithophane

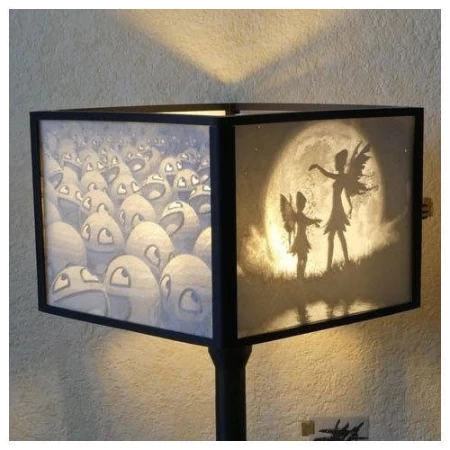

Traditionally, a lithophane denotes an etched or moulded work of art, usually done in very thin translucent porcelain which is only visible when illuminated with a backlight. The images produced by way of 3D printing with a lithophane change characteristics according to the source of the backlight. This is the distinguishing feature of these three-dimensional images.

Popular in History

The earliest recorded history of lithophane dates back to the 1800s. Back then, they were carved out of wax, moulded in plaster, cast and fired in porcelain. They took a backseat with the invention of photography. However, with the of 3D printing services, it is now possible to experience both!

The fine detailing and delicate nature of lithophanes can be best obtained on high-resolution stereolithography (SLA) 3D printer. FDM 3D printers might not be able to produce the superior quality of images obtained via SLA technology.

How It Works

There may be multiple tools for creating a lithophane photo frame, but almost all the same way. The first step involves the identification of the primary subject of the photo. Once this is done, the subject is embossed. The next step is the border of the frame. The final file is provided in a 3D format (for example, .STL)

What You’ll Need:

- SLA 3D printer

- White Resin

- Wash or Finish Kit

- Post-curing chamber

The Steps Explained

- Pick a photograph: High-resolution SLA 3D printers are capable of using any moderately contrasted photograph to create a highly detailed 3D image. However, if you choose an image that has low contrast (only because you love it so much), you can try to convert the colour photo into a black and white one. While you are at it, turn up the level of contrast or even erase the background (there are editing tools available for this one.)

- Generate a Free Lithophane:Now, convert the 2D image into a 3D lithophane model. You will find a number of free online 3D printing tools for this purpose. The most popular of these is a free online image-to-lithophane converter.

- 3D Print Highly Detailed Lithophanes:Obtain your3D printed lithophane by placing the flat side directly on the build platform. This ensures quick results. However, remember that vertically printing the lithophane also has its advantages. It enables you to obtain larger prints (185 mm by 145 mm.) Moreover, the latter technique also allows for more prints (up to 19 lithophanes) in one build. If you are a sucker for efficiency, we suggest you make use of the second option! Print the file in Standard White Resin at 50 microns for the best results. If you’re rushed for time, 100 microns will still give you great results.

- Post-Processing:This is a critical final step for any 3D printed parts. Finishing is crucial and, in the case of lithophanes, this step should be carried out extra carefully. Remember, you are dealing with an extremely delicate and thin part. Let the parts dry and only them remove them gently from the build platform. Cure them for 5 minutes at 40 °C.

Final Words of Advice

3D printed lithophanes are best obtained using white filament. However, one can use other colours as well, albeit they may not yield the best results. White filament works best due to its transparency and appears more vibrant and brighter when lit up with a backlight. With other colours, the contrast won’t be the same resulting in dull images.

Online 3D printing in India is waking up to the phenomenon of 3D printed lithophane. Remember, SLA 3D printers yield the best results when it comes to printing high resolution and extremely precise and detailed lithophanes in 3D.

Once you have your 3D printed lithophane, you can choose to place it on a window which has plenty of natural light. Or, you can simply place an LED backlight to create a lithophane lamp. 3D printed lithophanes are a great option in personalized gifts or even for home décor. Look for 3D printing in Pune that can bring you the best in this regard!